Glass Cutting Machine

- By:

- Date:2020/07/31

Glass cutting machine refers to a processing machine dedicated to glass processing and blanking. The automatic glass cutting machine includes an air-floating sheet feeding table arranged end to end and a double bridge interchange cutting table. As an improvement, the double bridge overpass cutting table is set between the leading straight beam and the second straight beam at the first part of the upper frame in the length direction, and the third straight beam and the fourth straight beam at the first part of the lower frame in the length direction. There is a glass conveying mechanism including a rotating shaft, a number of conveying wheels, a motor, and a belt; the air-floating film feeding table has a proximity switch connected to the power control circuit of the motor at the end of the length direction of the table to control the opening and closing of the motor. The upper end of the proximity switch is slightly lower than the table. As a further improvement, the double-bridge interchange type cutting table is provided with two vertical rolling components that block the glass on the leading straight beam and the second straight beam, and the four rolling components are arranged in a rectangular shape. In addition, it also has a manual breaking table, and the double bridge overpass cutting table and manual breaking table are arranged end to end.

In the normal operation of the glass cutting machine, there are many aspects that need to be paid attention to. In addition to the basic cutting speed, cutting thickness and cutting height, the cutting gas also requires constant attention. In order to improve the cutting quality of on-site automatic glass cutting machine, Shanghai Weihong has summarized several suggestions as follows on the research and development experience of automatic glass cutting technology for many years.

To use a fully automatic glass cutting machine, you first need to master the flame of the cutting nozzle. The key to adjustment is the gas source. Most of the on-site oxygen supplies oxygen to the pipeline. The purity and pressure of the oxygen can generally meet the requirements for use, but the gas is mostly bottled. Gas, a 30 kg bottle of gas, in the scale of 5 machines and 5 streams, the use time is about 2 hours. In this way, the gas source must be replaced in the middle, which will cause large fluctuations in gas pressure, which directly affects the gas flow and causes cutting Is not normal.

CONTACT US

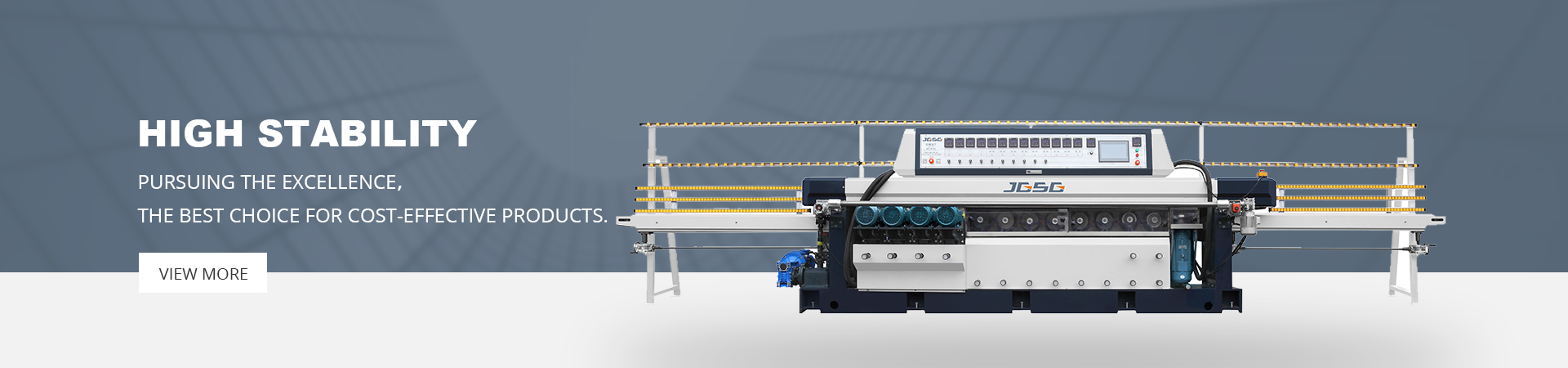

Foshan Shunde Jugang Shengong Glass Machinery Co., Ltd7

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us